Plastic profiles for point of sale

Technical innovations developed over the years in the POS and other sectors enable us to offer our customers a wide variety of imaginative solutions by combining techniques and adding new proposals.

– We respond to the needs of special finishes and tight delivery deadlines

– We combine several technical methods to offer comprehensive solutions

– Exclusive technology for surface treatments

Our proposal

Technical innovations developed over the years in the POS and other sectors enable us to offer our customers a wide variety of imaginative solutions by combining techniques and adding new proposals.

Some of these include chrome profiles in the pharmaceuticals sector, combining semi-transparent and opaque profiles, adding lighting to profiles for illuminated display fixtures and colour to lighting profiles, decorative metallic strips for electronic equipment displays and different woodgrain finishes.

Engineering solutions

With our experience and technical background, we know how to combine the results obtained in other sectors not commonly used on a specific project, giving us the capacity to propose and apply solutions that would not normally be found in our customer’s sector.

In the POS industry, there is a constant need to combine solutions from other sectors. With the addition of LEDs in display units, Polinter draws on its wide experience in the lighting sector.

Based on the decorative profiles originating in the furniture industry, we have added metallic chrome, mat aluminium and wood finished profiles and tubes according to customer specifications.

Our experience in the automotive sector, with metallic strip inserts, provides self-adhesive decorative elements.

We can also provide alternative materials on POS projects that require halogen-free components.

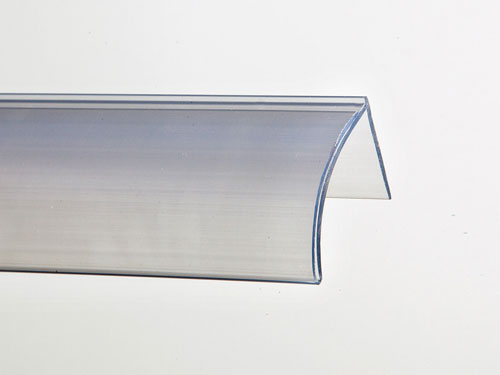

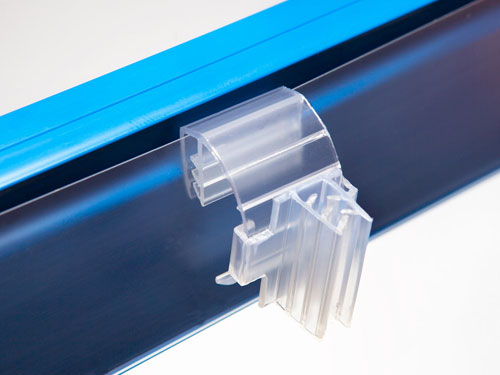

We have over 4,000 profile types at our disposal to respond to a wide variety of uses, including unforeseen events that occur at the end of a process that require immediate attention. Our catalogue (use this link to download in pdf format) features an extensive list to choose from.

Mould design and construction

Different components are used in the design and construction of display units, which frequently feature plastic profiles.

If our stock of existing moulds does not match customer requirements, we have the capacity to design and construct custom made solutions in our on-site facilities. Without this comprehensive service, the POS sector’s strict delivery deadlines are hard to meet. The entire design process, from the choice of materials, mould construction, final profile adjustments, etc., cannot be carried out quickly without an integrated coordination and close collaboration with customers.

Production

The POS and merchandising sector commonly requires short lead times, even on custom made projects. Our production capacity with product specific machinery allows us to make flexible production runs and guarantee fast delivery.

At the same time, our production capacity also enables us to quickly develop new moulds in our tooling facilities.

Raw materials

We use a wide range of polymers with different colour and finish treatments in the projects we design for the POS sector. We can also add recent market developments such as wood plastic composites (WPC) and biodegradable material.

Who we are

We have been developing specific solutions for customers in the merchandising sector since the early days, from the initial to the latest applications with the most innovative materials.

Special finishes

The POS sector also requires special finishes that make each of its projects unique, from standard mechanized profiles with special colours or custom-designed surface treatments to projects using profiles with different finishes such as glossy or woodgrain (Decoform) and chrome (Novocrom), etc. Our technical expertise and exclusive surface finishes, Novocrom, Decoform, Stilkrom and Fixaform, provide customers in the POS sector with several solutions for manufacturing display items and fixtures. R&D+i

Polinter has collaborated on several R&D+i projects with a special emphasis on the environment. Developing projects using biodegradable plastics enables us to apply these materials in limited use designs that can later be recycled into bio-compost.

We can also add natural wood fibres to our developments to give displays a natural wood look, enhancing the ecological aspect of the project.