Wide range of customized solutions

Mould design, engineering, extrusion and co-extrusion, R&D+i, raw material and colorant formulating and special finishes

Our company’s 30 extrusion lines of different sizes and technologies allow us to quickly produce different types of extruded and co-extruded profiles using a wide variety of polymers available on the market.

We draw on our vast experience to develop dedicated projects using imaginative, effective applications from several sectors to adapt commonly used processes to the special needs of our customers.

We rely on our own facilities to develop our comprehensive design and production process, including mould design using electro-erosion as well as mould maintenance and safekeeping. We adapt market-ready raw materials, formulations and colorants in our laboratory, where we work with all kinds of plastics, from conductive to biodegradable, in a constant search for new solutions that includes collaborating with different European research programmes.

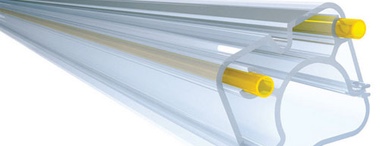

Polinter collaborates with the EXTRULIGHT project

In collaboration with the ASCAMM technology center, Polinter is part of the EXTRULIGHT project to investigate new design methodologies and manufacture of extruded profiles with optical quality for interior lighting. Project co-financed by the Ministry of Economy and Competitiveness.

Engineering solutions

– Custom project development

– Imaginative, effective solutions applied in different sectors

– Adapting standard processes to special needs

Mould design and construction

– Dedicated facilities for mould design and construction

– CAD-CAM design, electrical discharge machining manufacturing process

– We offer our customers a quick, agile response in creating specific moulds, maintenance and storage

R+D+I

– We elaborate our own solutions in our quest for continuous R&D+i

– We work with all kinds of plastics, from conductive to biodegradable

– We collaborate with several European research programmes

Innovation

– Comprehensive process in designing moulds, raw materials and colorants

– Technical expertise in different solutions and processes

– We reduce customer idea to market launch lead times

Raw materials

– Formulating raw materials and colorants

– Specific applications for each project and customer

– We use a wide range of products on the market

Production

– 30 extrusion lines of different sizes and technologies

– Flexibility to manufacture short and long production runs

– Comprehensive process from raw materials to final quality control

Special finishes

– We personalise and add value to our profiles

– Application in diverse sectors ranging from automotive to interior design

– Exclusive patents and tooling to customer specifications

Specialists in extrusion of plastic profiles

Polinter S.A. is a leading company in the extrusion and co-extrusion of plastic profiles with 60 years of industry experience. From our facilities located in Montcada i Reixac, Barcelona, we offer our customers vast experience and versatility in designing and manufacturing dedicated solutions and custom projects as well as a complete catalogue with over 5,000 solutions ready for application in all kinds of industrial and decorative projects.

Polinter exports to 30 countries, collaborates in several R&D+i programmes within the European Union and adheres to policies that encourage energy efficiency and recycling and reusing of resources.