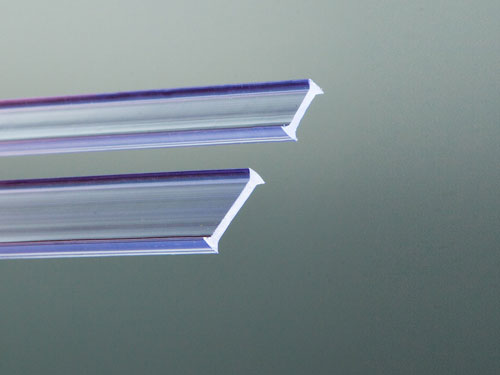

Plastic profiles for glass partitions

We have an extensive background in this industry, which has specific demands regarding functionality, efficiency and material resistance, and apply solutions from our catalogue and our technical and production capacities to customer projects to produce profiles that meet their exact standards of transparency and finishes.

– Profiles for all kinds of dividers and glass enclosures or partitions

– Functionality, transparency and UV resistance

– Profiles with specific solutions and special finishes

Our proposal in glass partitions

We provide plastic profiles to all sectors that work with glass partitions, shower enclosures, and dividers.

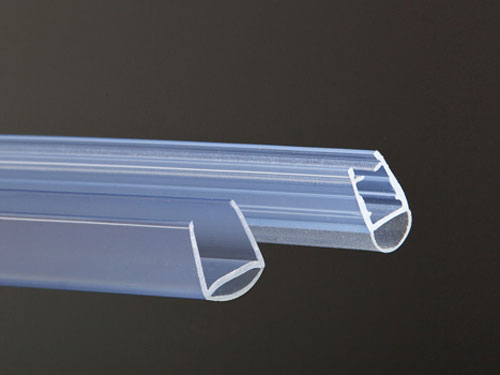

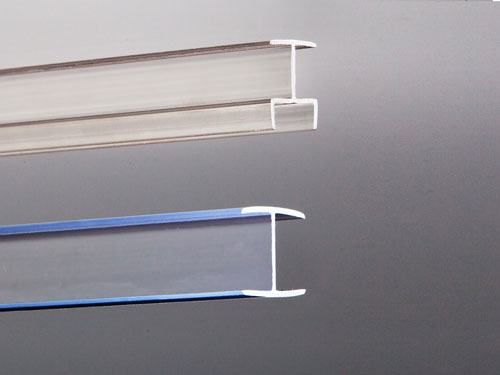

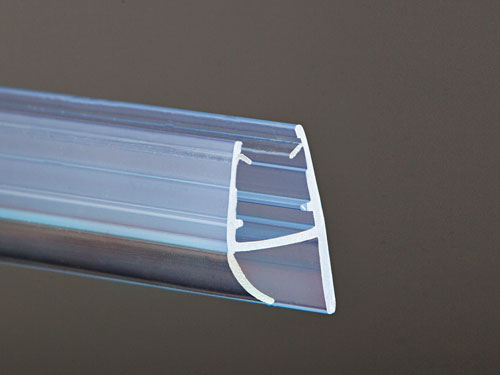

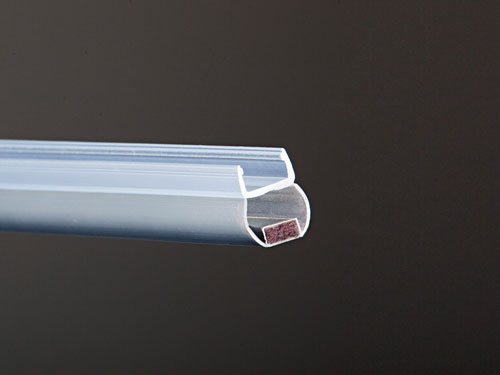

This sector is in constant evolution, so our offer includes new models of profiles for market demands, including rigid, flexible and co-extruded products, U and H shaped profiles, joints and other profiles suitable for use in all kinds of applications.

We use the best material for each project, including thermoplastic products such as PVC, PC, ABS, PE, PP, etc., with transparent, opaque, weather and UV resistant, textured, smooth or adhesive-free finishes. Some of our exclusive standards include “Decoform” and “Novocrom”.

Three factors define the quality grade of our products – functionality, transparency (on glass partitions) and UV resistance (on outdoor applications). Our capacity to formulate and combine the most suitable raw materials enables us to provide our customers with profiles that satisfy these basic characteristics and at the same time are also flexible and resistant to impact and pressure.

Our involvement in this kind of solutions goes beyond plastic profile development. We provide finishes that increase the functionality of many sophisticated projects, from gliding surfaces and decorative elements to magnetic applications.

We also provide the bath sector with special colours, custom surface treatments, glossy enamels, chrome and mat aluminium, as well as applications using WPC profiles. We apply specific solutions to the sector by combining the products in our catalogue with other materials found in different industrial applications with proven effectiveness. For special needs, we develop new solutions in our tooling and materials divisions.

Furthermore, our catalogue evolves to keep up with a growing market. Before beginning any enclosure project we recommend our customers contact our sales division to check whether an existing solution can be applied to a new project and obtain assessment on any new application available.